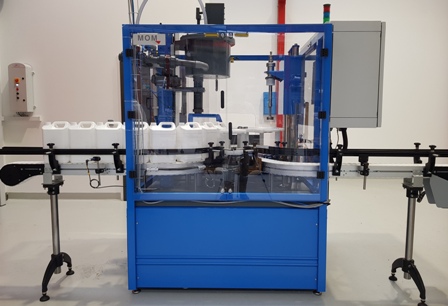

Spice filling machine

Regarding dosing technology, it is often thought that the best precision will be obtained with weight filling. It’s not always accurate. Weight dosing is effective for doses above approximately 50g. For the dosage of the grains (like the dawn in grains) we can also favor the weight, because of the weight of each grain. For …