Chicory filling machine: the essentials in 30 seconds

Technical summary:

Chicory (instant/soluble, granulated, or ground) is fragile, sensitive to moisture, and can be dusty depending on particle size.

Vertical auger filling machines chicory cleanly, accurately, and without damaging the product.

The choice between filling by volume and filling by weight for dosing chicory depends on the speed, the dose to fill, and the accuracy required.

This article focuses primarily on industrial filling solutions for soluble, granulated, or ground chicory—whether blended or not (with coffee, chocolate, etc.). If you need to fill chicory, a vertical auger filler is typically well suited.

Soluble, granulated, or ground chicory: what constraints affect filling?

Before choosing an industrial chicory filling machine, you need to consider very practical product constraints: fragility, moisture sensitivity, and sometimes dustiness.

Fragility: how to avoid damaging chicory

Chicory is a delicate dry product: it must be handled carefully to preserve its quality.

That’s why, for an industrial chicory filling application, technologies such as vibratory trough dosing should be avoided. Even if this approach can be effective for packaging pieces (candies, savory biscuits, etc.), it can damage chicory due to vibration—impacting quality and consumer satisfaction.

Moisture: why chicory degrades quickly

Chicory has a key characteristic: it absorbs ambient moisture very easily. You can notice it quickly on skin contact—the product can degrade almost instantly. Physically, it becomes sticky, almost liquid.

In production (high volume or smaller roasters), the challenge is therefore to fill quickly and accurately, without compromising quality.

Ideal solution: work in a controlled humidity environment to keep the product stable.

Dustiness: how to handle fines

Depending on roasting fineness, chicory can have different textures and may be dusty.

In that case, it may be necessary to provide a dedusting / dust extraction system:

-

at the dosing funnel / hopper throat,

-

and at the product feeding point into the packaging machine hopper.

Note: the goal is not to vacuum the product. The extraction system must be sized to remove fines without aspirating usable material.

What technology should be used for an industrial chicory filling machine?

Technologies that can harm chicory

Vibratory trough dosing: avoid

A vibratory trough can be suitable for other products (especially pieces), but for chicory it can cause degradation due to vibration.

Pneumatic conveying: validate through testing

Pneumatic transfer systems can be very effective in some cases, but they can also damage chicory and compromise product quality.

The recommended approach is simple: run a test with a machine builder to confirm (or not) the impact of pneumatic conveying on your chicory quality.

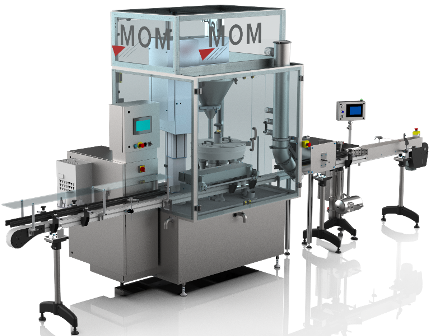

MOM recommendation: vertical auger dosing

For filling soluble chicory, or chicory blended with coffee beans, vertical auger dosing is particularly suitable:

-

accurate dosing,

-

fast dosing,

-

gentle dosing (without damaging the product),

-

no segregation (coffee + chicory blend, or chocolate, etc.).

Note: If you are filling chicory in dry form, a vertical auger filling machine is well suited.

| Technology | Product risk | When it fits | Why |

|---|---|---|---|

| Vibratory trough | High (vibration → degradation) | Better for pieces (not chicory) | Excess vibration can alter chicory |

| Pneumatic conveying | Variable (to be validated) | Depending on your process, after testing | Can damage chicory: testing recommended |

| Vertical auger | Low (gentle solution) | Soluble chicory + coffee/chicory blends | Accurate, fast, gentle, no segregation |

How to prevent segregation in a chicory and coffee blend?

Why segregation happens

When dosing a chicory and coffee blend, the risk is creating flow variations that can cause segregation—leading to a non-homogeneous result in the package.

What a vertical auger brings

Vertical auger dosing provides a stable and gentle feed, helping achieve segregation-free filling while preserving product integrity.

Product feeding: gravity, screw, pneumatic… what should you prefer?

Choosing the dosing technology is not enough: you also need to define how the machine will be fed with product.

MOM recommendation: gravity feeding and a short horizontal screw

Ideally, chicory is fed by gravity via a short horizontal screw.

Why?

-

screws that “lift” products are often difficult to disassemble for cleaning;

-

in the context of a product consumed by living beings, high-quality cleaning is essential;

-

and lifting screws can also damage chicory.

Cleaning: key checkpoints

Before choosing an industrial chicory filling machine, make sure to check:

-

Are the product-contact parts easy to disassemble?

-

Does disassembly enable high-quality cleaning?

-

Does the chosen solution limit the risk of product damage?

-

How simple and fast is disassembly (direct impact on downtime)?

Attend production trials

To validate all these points, the most reliable approach is real-world validation: request to attend production trials.

During these trials, you will be able to verify:

-

dosing accuracy,

-

product preservation,

-

throughput,

-

simplicity and speed of disassembly for cleaning.

For decades, MOM Packaging has been producing vertical auger filling machines for hygroscopic products such as chicory, instant coffee, and pharmaceutical powders. MOM Packaging has been designing and manufacturing filling machines since 1927, with strong expertise in powders and dry products.