In modern industry, automation of production processes has become essential to ensure increased efficiency, reduced production times and consistent product quality. One of the key steps in production is the accurate and fast filling of products into suitable containers. That’s where industrial filling machines come in. This specialized equipment is designed to automate the filling process in various industries such as food, cosmetics, pharmaceuticals, chemicals and many others.

Industrial filling machines offer a multitude of benefits, such as improved efficiency and productivity, reduced labor costs, and the elimination of human error. They can fill different types of products, from liquids to powders to viscous products, into a variety of containers such as bottles, vials, jars or bags.

In this article, we will explore in detail what an industrial filling machine is. We will examine the different functions, components, technologies and types of filling machines available on the market. We will also look at the importance of maintenance and safety of these machines to ensure optimal operation. First, let’s look at the question: what is an industrial filling machine?

The role of industrial filling machines:

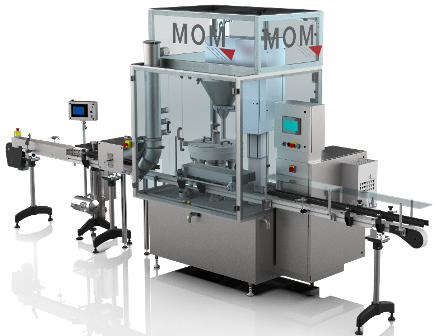

Industrial filling machines are specialized equipment designed to automate the filling process in the production field. They are used in a variety of industries, such as food, cosmetics, pharmaceuticals, chemicals and many others. These machines offer high accuracy, increased productivity and reduced human error compared to manual filling. They are capable of filling different types of products, including liquids, powders, granules, viscous products, in various container sizes.

Filling technologies used:

Industrial filling machines use different dosing technologies to ensure accuracy and consistency of filling. Here are some of the most commonly used technologies:

- Weight dosing: In this case, the weight of the product is measured using precise scales, thus ensuring accurate filling, regardless of the density or viscosity of the product.

- Volumetric dosing: This method uses volumetric pumps or dosing cylinders to measure the precise volume of the product to be filled.

- Level dosing: This method uses level sensors to detect and maintain the desired fill level in each container.

- Flow metering: The flow rate of the product is measured to determine the amount to be filled, which is particularly useful for liquid or bulk products.

Benefits of industrial filling machines:

The use of industrial filling machines offers many benefits to manufacturers. First, they greatly improve efficiency by automating the filling process, reducing labor costs and increasing production capacity. In addition, these machines ensure accurate and consistent filling, eliminating variations due to human error. They also reduce waste, as they optimize product usage by avoiding overfilling. Industrial filling machines also help to improve overall product quality, avoiding cross-contamination and ensuring a healthier working environment.

Types of industrial filling machines:

There are a variety of industrial filling machines available, tailored to the specific needs of each industry. Here are some common examples:

- Liquid filling machines: These are used to fill liquid products such as water, beverages, liquid chemicals, oils, etc.

- Powder filling machines: They are suitable for filling powder products such as spices, food supplements, powdered pharmaceuticals, etc.

- Granule filling machines: They are specially designed to fill granular products such as grains, cereals, pet food granules, etc.

- Viscous product filling machines: These are used for thicker products such as sauces, creams, gels, pastes, lotions, etc.

- Aseptic filling machines: These are used in the pharmaceutical and food industries for filling products that require a sterile environment.

Maintenance and safety:

To ensure optimal operation, industrial filling machines require regular maintenance. This includes regular cleaning of product contact parts, replacement of wearing parts, checking and calibration of dosing devices, and general inspection for possible problems. In addition, industrial filling machines are equipped with safety features such as sensors, interlocks and protective barriers to prevent accidents and ensure operator safety. Augmented reality maintenance solutions also exist to increase the speed of assembly and disassembly operations.

In conclusion, industrial filling machines are essential tools for automating and optimizing filling processes in various industries. They offer increased accuracy, efficiency and productivity compared to manual filling. With different dosing technologies adapted to each type of product, these machines ensure accurate and consistent filling in a wide range of containers. Regular maintenance and adherence to safety standards are also essential to ensure optimal operation and extend the life of the filling machines. By exploring in detail the features, benefits and types of industrial filling machines, we have answered the initial question: what is a filling machine?