Choosing the right technology to fill powder

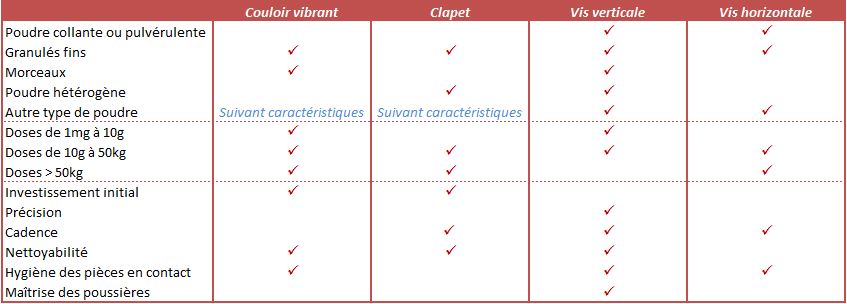

There are different technologies to fill powder products, each with their own set of advantages: the vibrating conveyor, the valve, thevertical screw and thehorizontal screw. Which technology is the right one for you? The characteristics of your powder and the performance you expect from your filling machine will help determine the solution best fitted to your needs.

A vibrating conveyordoses your product by making a conveyorthat carries your powder vibrate.The product is dosed by weight-filling. The simplicity of this process helps keep the technology’s cost down.However, the vibrations, by shaking your powder, can create dust that is difficult to contain. Vibrating conveyors are also slower than other dosing technologies available and are not suitable for heterogeneous powders as the vibration process will break down the different components of your product. Given this, a vibrating conveyor is mostly used for dosing chunks. In the food industry for example, candy and pasta are oftendosed with a multi-head weigher

Powder-dosing with a valve is a simple process: a flap, hatch or valve slide opens to fill the container placed underneath. Installed directly beneath a mixer or a big bag, valves are rarely used in industry. Indeed, their main inconveniencesare their lack of precision, their creation of dust during the release of powder, as well as their difficulty to dose sticky or adhesive powders.Indeed, the opening and closing of the valve generate uncontrolled projections of powder, which lead to dust. And sticky or adhesive powders can create a clog at the valve, whichwill stop its functioning. This technology is always combined with weight-filling.

Vertical screwdosing is the most commonly used technology. AnArchimedean screw located in a funnel drags your powder into the container. This process can be used with weight-filling or with volumetric filling and has the advantage of combining high precision, pace and cleanability. According to the specificities of your powder, the manufacturer will determine the characteristics of the screw best adapted to your needs. The need to have a “tailor-made” screw entails additional costscompared to the two previous technologies. In return, an adapted dosing screw means that you will be able to dose all types of dry products: homogeneous or heterogeneous, fusant, caky, adhesive, fragile,… What is more, given that your powder is channeled between the blades of the dosing screw, dust is contained for even the most powdery products.

Horizontal screw dosing is most often used to fill powder or dry products large containers (over 50kg). When used for dosing purposes, such screws tend to somewhat agglomerate powder. The main watch-out for this technology is the release of powder at the end of each dosing.When the screw stops, the angular position of the screw’s last blade is not always identical – this means that the quantity of powder to fall at the end is not always the same. This quantity of powder is directly dependent on the diameter of the screw. Furthermore, the horizontal screw is further up from the container than a vertical screw, meaning that the fall distance is bigger for a horizontal screw which can also generate weight variations. Horizontal screws can equally lead to the segregation of heterogeneous products. Finally, as they tend to agglomerate powder, these screws can create areas of stagnation of the product and a heating of the product. Horizontal screws are mostly used to feed intermediary hoppers in vertical screw machines.

In order to best choose your filling technology, it is important to specify your expectations in terms of doses, rate and precision, as well as to know the characteristics of your powders or to ask the manufacturer to determine these.

Find all articles by the Dosing Experts here