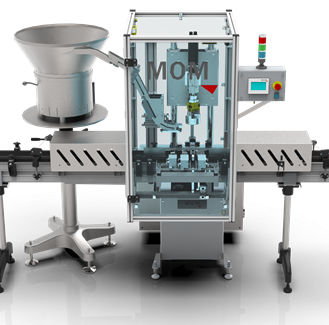

Industrial capping machines play an essential role in the product sealing process in various industries. They offer an automated solution for applying caps on containers such as bottles, flasks, jars, tubes, etc. These machines guarantee a secure and hermetic closure, thus preserving the quality, freshness and integrity of the products.

In this article, we will explore in detail what an industrial capping machine is, its functions, types and importance in production processes, and try to go beyond the initial question “What is a capping machine?”

The role of capping machines:

Industrial capping machines are designed to automate the process of capping containers in the food, beverage, cosmetics, pharmaceutical and many other industries. They allow for accurate, efficient and consistent application of closures, reducing human error and quality variations. These machines are equipped with cap positioning and fastening devices, ensuring optimal sealing to prevent leakage or contamination. They are available in different speeds depending on the demand.

Types of capping machines:

To answer our question: What is a capping machine, we will explore the different types of industrial capping machines. Each type of machine is adapted to different types of corks and containers. Here are some common examples:

- Screw capping machines: These machines use screwing heads to apply screw caps to containers. They provide a precise, tight fit for an airtight closure. Screw cap machines are suitable for plastic bottles, glass bottles and containers with screw caps. They are widely used in the beverage, food and household products industries.

- Pressure capping machines: These machines use pressure mechanisms to push the caps into the containers, ensuring a secure closure. They are suitable for pressure caps such as snap caps, clip caps, etc. Pressure capping machines are commonly used in the soft drink, chemical and personal care industries.

- Capsule capping machines: These machines apply metal or plastic caps to containers, providing additional protection and aesthetic appeal. They are commonly used in the wine, spirits, and high-end product industries. Cap sealing machines provide a tight seal and ensure product integrity. They also offer customization options in terms of colors and logos.

- Corking machines with cork stoppers: These machines are specially designed for corking wine or champagne bottles with cork stoppers. They guarantee a hermetic corking while preserving the quality of wines. The cork stopper machines are often used in wine cellars, wineries and champagne industries where the cork stopper tradition is privileged.

- Synthetic stopper machines: These machines are designed to apply synthetic stoppers to containers. Synthetic stoppers offer an alternative to cork and are often used in the wine industry. Synthetic stopper machines provide a tight seal and can be adjusted for different stopper sizes.

- Flapper Closure Machines: These machines are specifically designed for containers with flapper closures. Flapper closures are commonly used in the beverage and food industry. Clamshell capping machines allow for a precise and secure application of these closures, ensuring a tight seal and making it easy for consumers to open the container.

The importance of capping machines:

Industrial capping machines offer many benefits to manufacturers. They increase productivity by automating the capping process, reducing labor costs and improving production line efficiency. The machines ensure consistent application of closures, reducing the risk of leaks, contamination and product damage. In addition, they can achieve high throughput rates, which are suitable for large-scale industries.

The capping machines also offer flexibility, as they can be adjusted to accommodate different types and sizes of caps, as well as different container formats. This allows manufacturers to meet a variety of market demands and diversify their product offerings. In addition, these machines are equipped with quality control mechanisms that check for proper closure and report any anomalies, thus helping to maintain high standards of product quality and safety.

In addition, capping machines help to improve the brand image of companies by ensuring consistent and reliable product closure. Consumers often associate a quality closure with a quality product, which increases customer confidence and satisfaction. Capping machines also allow for increased traceability, as they can be integrated with tracking and control systems, recording data such as the date and time of capping, the type of cap used, etc.

In conclusion, industrial capping machines are essential equipment in the product sealing process. They optimize the capping process by automating operations, ensuring accurate and consistent application of caps, and helping to maintain high standards of product quality, safety and traceability. Manufacturers who invest in these machines benefit from increased productivity, improved brand image and customer satisfaction. Industrial capping machines are a key element in ensuring the competitiveness and success of companies in the marketplace. They enable manufacturers to meet the increasing demands of consumers for product quality, safety and reliability. So we explored the question: What is a capping machine?