In industrial production, product labeling plays an essential role in ensuring effective identification, tracking and marketing. This is where the industrial labeler comes in, a specialized piece of equipment designed to automate and simplify the process of applying labels to a wide variety of products. Whether it’s in the food, pharmaceutical, cosmetics or any other industry that requires accurate and consistent labeling, the use of an industrial labeling machine can provide significant benefits.

In this in-depth article, we will explore the question “What is an industrial labeler?”. To do so, we will delve into the world of industrial labeling machines, exploring in detail how they work, their different types, their benefits and their uses. Whether you’re an entrepreneur looking to improve the efficiency of your production line, a quality manager seeking regulatory compliance, or a packaging professional looking for innovative solutions, this guide will provide you with the information you need to understand and exploit the potential of an industrial labeler.

What is an industrial labeler?

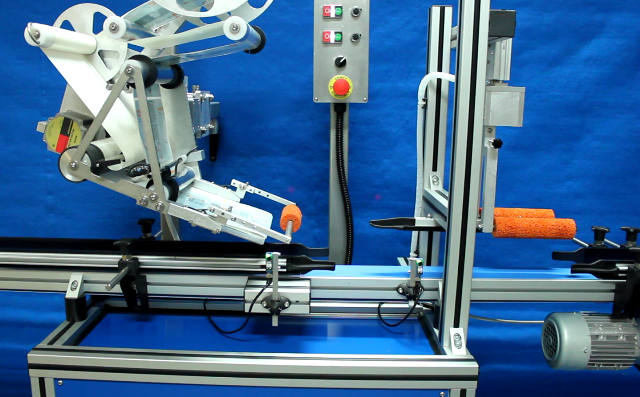

An industrial labeler is a machine designed specifically to apply labels to products or packages. It is equipped with label unwinding mechanisms, printing devices (in some cases), cutting systems and application devices. These machines are designed to handle large production volumes, providing a fast and automated solution for product labeling.

How does an industrial labeler work?

The industrial labeler works by following a specific process. First, the labels are loaded into the machine’s feeder system. Next, labeling information, such as barcodes, lot numbers or expiration dates, is entered into the system or printed directly onto the labels using the built-in printer. Finally, the labels are applied to the products or packages using an appropriate application mechanism, such as a pressure roller, air blower or adhesive application system.

The different types of industrial labeling machines:

There are several types of industrial labeling machines adapted to specific needs. The main types are :

- Automatic labeling machines: These machines operate in a fully automated manner, feeding the labels, printing the required information and applying the labels to the products at high speed.

- Semi-automatic labeling machines: These machines require manual intervention to load the labels and/or position the products. They are more suitable for small and medium productions.

- Pressure labellers: They apply the labels using a pressure roller to ensure a firm adhesion on the products.

- Air blower labelers: Use compressed air to apply labels to surfaces, ideal for sensitive products.

- Adhesive labelers: They apply labels precisely to products using an adhesive application system, often used in industry.

Advantages and uses of industrial labeling machines:

Industrial labelers offer many benefits to businesses. Here are some of the main benefits and uses:

- Improved Efficiency: Industrial labelers speed up the labeling process, reducing the time it takes to label products. This increases the overall productivity of the company.

- Accuracy and Consistency: With their automated operation, industrial labeling machines ensure accurate and consistent application of labels to each product. This reduces human error and ensures consistent product presentation.

- Flexibility: Industrial labeling machines are often equipped with features that allow for quick changes in label formats and types. This provides flexibility for companies that produce different types of products that require specific labels.

- Regulatory Compliance: Many industries require certain information on products, such as ingredients, warnings or lot numbers. Industrial labelers facilitate regulatory compliance by ensuring accurate and legible application of this information.

- Traceability and inventory management: Industrial labeling machines can integrate inventory tracking and management capabilities. They can generate unique barcodes or serial numbers, making it easy to track products throughout the supply chain.

Tips for optimal use of industrial labeling machines:

To get the most out of your industrial labeler, here are some helpful tips:

- Choose the right type of labeler for your specific needs. Consider the size of your products, production volume, types of labels required, etc.

- Be sure to maintain your labeler according to the manufacturer’s instructions. Clean rollers, printheads (if applicable) and check ink or adhesive levels regularly.

- Use high-quality labels for long-lasting results. Make sure labels are compatible with your labeler and have enough adhesive to withstand environmental conditions and product handling.

- Properly train your operators on how to use the labeling machine. They should be familiar with label loading procedures, proper settings and safety precautions.

- Perform regular checks to verify alignment and accuracy of label application. This allows for early detection of any problems and ensures consistent quality results.

Industrial labelers are indispensable tools for companies that need to quickly and accurately label their products. With their automated operation, they improve efficiency, accuracy and consistency of labeling. Industrial labelers also offer improved flexibility, regulatory compliance, traceability and inventory management.

For optimal use of industrial labeling machines, it is important to choose the right type of labeling machine for your specific needs. Regular maintenance, use of high quality labels, proper operator training and regular checks are also essential. There are augmented reality solutions to help with maintenance and regular checks.

By investing in an industrial labeling machine and using it correctly, your company can benefit from faster production, fewer errors and better regulatory compliance. Don’t hesitate to consult with industrial labeling machine manufacturers for additional advice and to find the model that best suits your needs.

In conclusion, an industrial labeler is an essential tool for companies looking to automate and improve their labeling process. By understanding how it works, the different types available, and by following the tips on how to use it, you can maximize the efficiency and quality of your labeling operations.

If the question “What is an industrial labeling machine?” is still unclear to you, feel free to consult with industrial labeling machine manufacturers for additional guidance in finding the right model for your specific needs. Investing in the right industrial labeling machine can significantly improve your labeling process, increase your operational efficiency and enhance the quality of your products.