Piston dosing to fill fluid and viscous liquids

Piston dosing is a volumetric dosing technology that is particularly efficient to fill viscous and pasty liquids (such as honey, glue, cream, etc). When classic gravity flow is not enough for your product, it is necessary to “push” it in its container. That is the piston’s role.

There are two steps in piston dosing. The first step is the suction: your product is sucked into a cylinder. The course of the piston in the cylinder enables you to vary the dose. According to your doses, the manufacturer will design shorter or longer cylinders, with smaller or larger interior diameters. The second step is the delivery of your product: the liquid is “pushed” into its container. To avoid any drops or dribble between the dosing nozzle and the container, the manufacturer will be able to adapt the nozzle to your product.

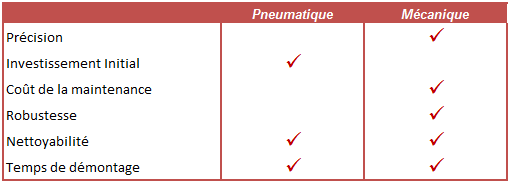

When it comes to piston-dosing, two technologies co-exist: pneumatic pistons and mechanical pistons. As they each have their own characteristics, the technology best suited to your product will depend on your needs.

With the pneumatic piston, the translation movement of the piston in the cylinder’s chamber is realized by a pneumatic actuator. Its main advantage is an initial cost slightly lower thanfor a mechanical piston. A pneumatic piston requires a reliable compressed air network to limit the imprecisions of its dosing. Mostly used for low added-value products, pneumatic piston-dosing is energy and maintenance-intensive.

With the mechanical piston-dosing, the pneumatic actuator is replaced by a cam. Independent of the quality of the compressed air network, mechanical piston-dosing gives greater precision. More robust than the pneumatic piston-dosing, it requires less maintenance. It is often chosen for its adaptability and speed in dosing.

Regarding their cleanability and the dismantling of the pieces in contact with your product, both technologies are equivalent and will depend on the craftiness of their manufacturer. Both are compatible with Clean In Place (CIP).

In a nutshell, the piston-dosing technology matching your needs will vary according to each one of your projects.

Find all articles by the Dosing Experts here