Filling liquid chlorine products

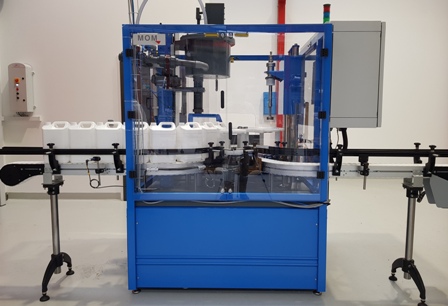

Otherwise, machines for filling liquid chlorine products should have the same advantages as other equipment: Simplicity of size changes (fast and without tools), Nozzles adapted to the products (especially nozzle trays for foaming products), The possibility to use the equipment for non-chlorinated products. PVC filling machines by MOM MOM designs and manufactures high speed automatic …